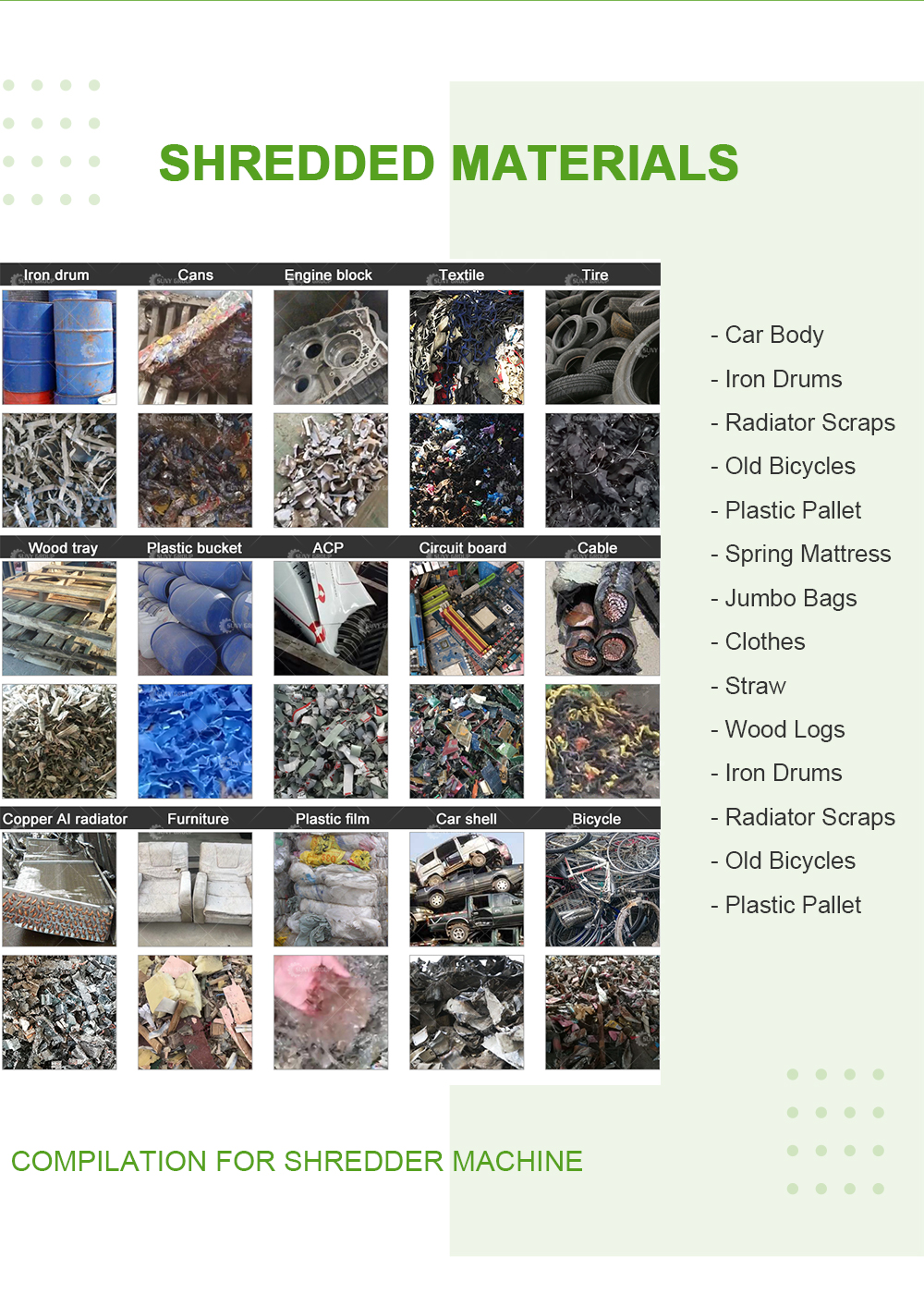

The SUNY GROUP Double Shaft Shredder is a powerful machine for a wide range of metal materials. Designed for heavy-duty industrial applications, this shredder effectively shreds materials such as stainless steel, brass/copper, alloys, carbon steel and aluminum, making them easier to handle, transport and further process for recycling or disposal.

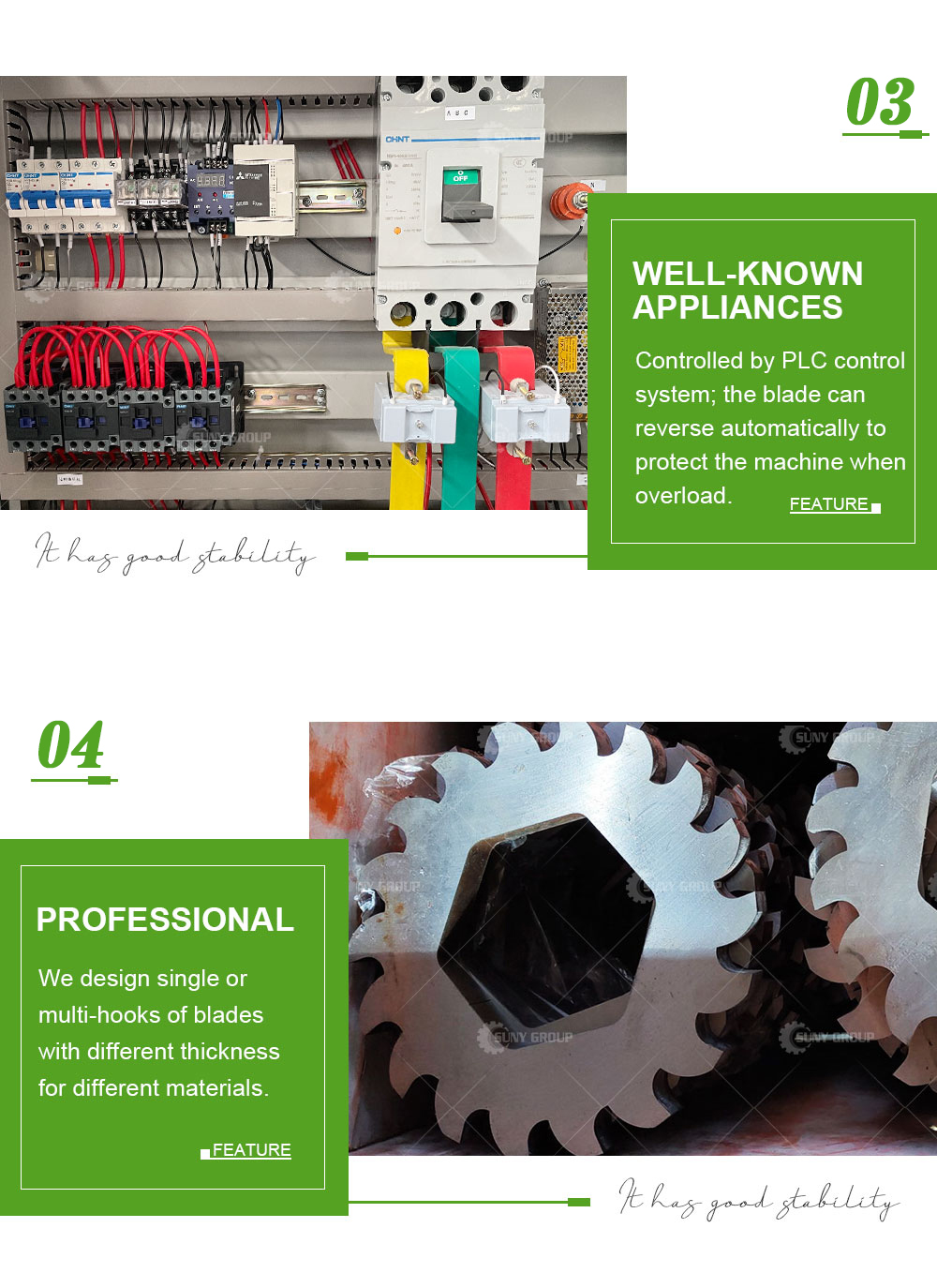

Designed for durability and performance, the SUNY Double Shaft Shredder is ruggedly constructed and weighs approximately 3-36t. Manufactured in Henan, China, this heavy-duty Double shaft shredder undergoes rigorous quality inspections, including video factory inspections and mechanical test reports, ensuring reliable operation from the start. The heart of the system is controlled by a PLC, providing enhanced operational control and automation.

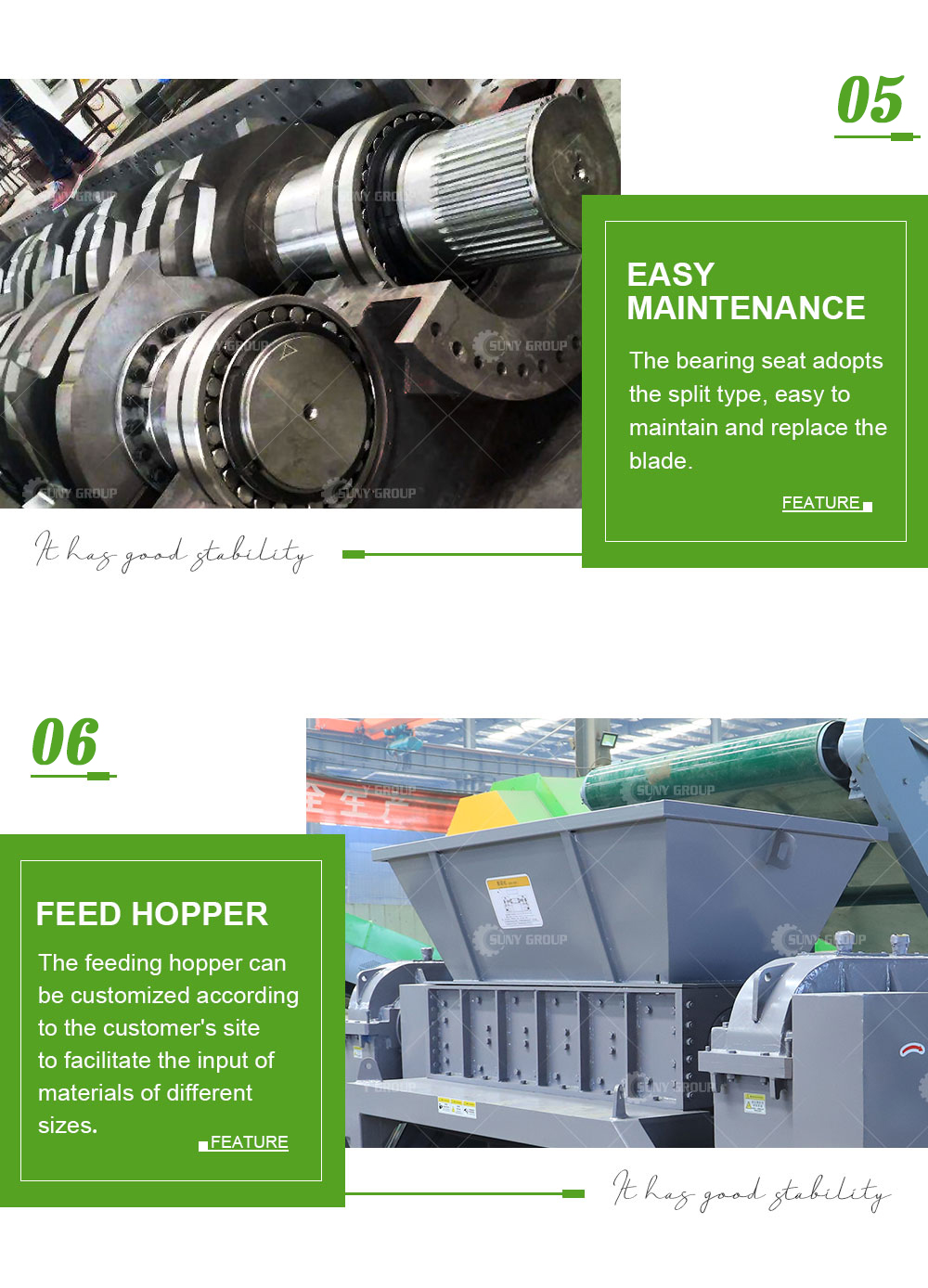

The shredder operates on a powerful shear and tear principle. The PLC control system is driven by a powerful 11-160kw watt motor, which transmits torque to two independent cutter shafts through a speed reducer. The cutter shafts are equipped with durable blades that rotate in opposite directions. The powerful meshing action effectively grabs, tears and shears the input material, significantly reducing its volume. The shredded material is then discharged for subsequent processing.

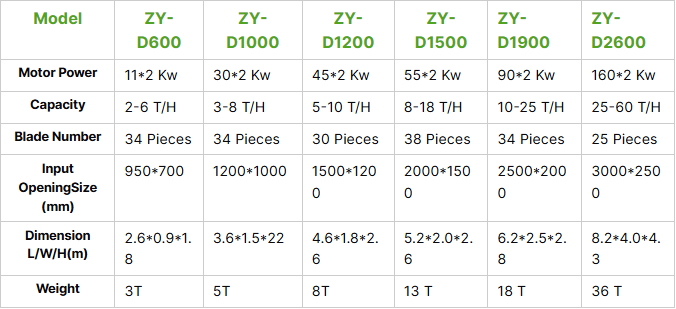

With a capacity range of 2 – 60t/h, SUNYDouble-shaft shredders are designed for high throughput operations. Their versatile selling point is the ability to process a wide range of metal types, making them a versatile tool for scrap metal recycling facilities, manufacturing plants, and waste management operations. Backed by a one-year warranty and available in custom colors upon request, SUNY Double-shaft shredders provide a reliable and efficient solution for your metal scrap reduction needs. Ensured to meet the latest engineering and manufacturing standards.

Power(kw)

11-160kw

Capacity

2-60t/h