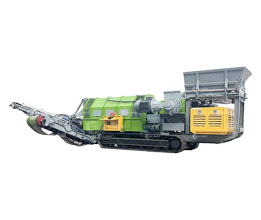

shredder to handle wet organic waste

Wet organic waste is messy, heavy, and notoriously difficult to manage. From food scraps and kitchen waste to agricultural residues and biodegradable sludge, wet organic waste can quickly become a costly, smelly, and inefficient problem if handled improperly.

That’s where a shredder designed to handle wet organic waste changes everything.

These machines are not just about size reduction—they are about efficiency, hygiene, cost control, and sustainability. Whether you run a food processing plant, municipal waste facility, farm, hotel, or composting operation, the right shredder can transform waste from a liability into a resource.

What Is a Shredder for Wet Organic Waste?

A wet organic waste shredder is a heavy-duty machine engineered to process high-moisture, biodegradable materials without clogging, corrosion, or performance loss.

Unlike standard dry-material shredders, these machines are designed to handle:

- Food waste with high water content

- Vegetable and fruit scraps

- Meat, fish, and bone residues

- Sludge-like organic byproducts

- Agricultural waste mixed with liquids

The goal is simple: reduce volume, improve downstream processing, and create uniform material for composting, anaerobic digestion, or recycling.

Why Wet Organic Waste Needs Specialized Shredders

Wet organic waste behaves very differently from dry materials. It sticks, smears, ferments, and corrodes. Using the wrong equipment leads to frequent jams, high maintenance costs, and downtime.

Key challenges include:

- High moisture levels (often 60–90%)

- Stringy or fibrous textures

- Rapid bacterial growth and odors

- Acidic liquids that cause corrosion

Specialized shredders solve these problems with reinforced shafts, anti-wrapping blades, sealed bearings, and corrosion-resistant materials.

7 Powerful Benefits of Using a Wet Organic Waste Shredder

1. Up to 60% Volume Reduction

Shredding significantly reduces waste volume, lowering transportation and storage costs. Studies show that size reduction can cut hauling frequency by nearly half.

2. Faster Composting and Digestion

Uniform particle size increases surface area, speeding up composting and anaerobic digestion by 20–40%.

3. Odor and Pest Control

Shredding enables faster processing, reducing exposure time and minimizing odors and insect attraction.

4. Improved Hygiene and Safety

Automated shredding reduces manual handling of decomposing waste, improving workplace hygiene and safety.

5. Seamless Integration with Waste Systems

Wet organic waste shredders work perfectly with:

- Screw presses

- Dewatering systems

- Biogas digesters

- Compost turners

6. Lower Disposal Costs

Less waste volume means lower landfill fees and compliance costs—especially critical as organic waste regulations tighten worldwide.

7. Strong Sustainability Impact

Organic waste accounts for over 44% of global municipal solid waste. Shredding supports circular economy goals by enabling recycling instead of landfilling.

A shredder designed to handle wet organic waste is more than a machine—it’s a strategic investment in cleaner operations, lower costs, and a greener future.

By reducing volume, improving processing speed, and eliminating common handling problems, these shredders empower businesses and municipalities to turn organic waste into opportunity.

If you’re serious about efficiency, compliance, and sustainability, the right wet organic waste shredder can be the game-changer your operation needs.

Contact Us

Address

Henan Communication Industrial Park, Economic Development Zone, Zhengzhou City, Henan Province, China