How does a mobile shredder work?

How Does a Mobile Shredder Work?

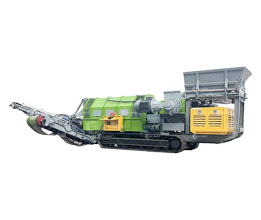

A mobile shredder is a highly versatile and powerful piece of equipment, distinct from its stationary counterparts due to its self-contained, portable nature. Specifically, many modern mobile shredders are track-mounted, meaning they are built on robust, continuous tracks, allowing them to navigate challenging terrain and move directly to where the material needs processing. This brings the shredding capability directly to the source, offering unparalleled flexibility and efficiency across various industries.

The Core Principle

At its heart, a mobile shredder operates on the same fundamental principles as stationary shredders, employing either single shaft or double shaft shredding technology. The defining characteristic is its integrated mobility via tracks. This means the entire system—including the shredding mechanism, power unit, material feeding system, and discharge conveyor—is designed for easy self-propulsion and rapid deployment across diverse sites.

Key Components and Operation

- Track-Mounted Mobility: The most distinguishing feature. Instead of being towed, these shredders use heavy-duty tracks, similar to an excavator or bulldozer. This enables them to traverse rough terrain, climb inclines, and position themselves precisely in quarries, demolition sites, landfills, or remote logging areas, eliminating the need to transport vast amounts of material to a central facility.

- Power Unit: Mobile shredders are typically powered by robust diesel engines. These engines drive the sophisticated hydraulic systems that operate the shredding rotors, automated feeding mechanisms, and integrated discharge conveyors. The engine’s size and power output are critical for handling a diverse range of challenging materials continuously.

- Feeding System: Materials are loaded into a large hopper, often using an integrated grapple, excavator, or even a front-end loader. An automated feeding system, such as a hydraulic ram or walking floor, ensures a consistent and controlled flow of material directly into the shredding chamber. This steady supply optimizes the shredder’s throughput and efficiency.

- Shredding Mechanism: This is where the magic of size reduction happens. Depending on the specific model and its intended use, a mobile shredder will feature either:

- Single Shaft: Equipped with a single rotor of knives cutting against a stationary blade, often paired with a screen for precise control over the output particle size.

- Double Shaft: Featuring two counter-rotating shafts with intermeshing teeth, designed for aggressive tearing and ripping of tougher, bulkier, or contaminated materials, typically without a screen for higher volume processing.

- Discharge System: Once the material is shredded to the desired size, it’s efficiently discharged, usually onto an integrated, adjustable conveyor belt. This allows the processed material to be neatly piled, loaded directly into another transport vehicle, or fed into subsequent processing equipment like screens, magnetic separators, or balers.

Why Track-Mounted Mobile Shredders?

The paramount advantage of a track-mounted mobile shredder is its unmatched flexibility and self-sufficiency. It drastically reduces logistical costs and environmental impact by processing waste directly on-site. These powerful machines are invaluable for operations in demolition, land clearing, municipal solid waste (MSW) management, biomass production, and large-scale recycling, offering a highly efficient and adaptable solution for material reduction wherever it’s needed.

Contact Us

Address

Henan Communication Industrial Park, Economic Development Zone, Zhengzhou City, Henan Province, China