Can a suny group`s shredder shred TPE?

Thermoplastic Elastomers (TPE) are everywhere—from automotive seals and medical tubing to shoe soles, wires, and flexible consumer products. As TPE usage grows, so does the recycling challenge. Many recyclers and manufacturers ask a critical question before investing in equipment: Can shredder shred TPE efficiently and reliably? The short answer is yes

In this in-depth guide, we’ll break down how SUNY Group shredders handle TPE, what makes TPE tricky to shred, which shredder types work best, and how to maximize output without clogging, melting, or downtime. If you’re dealing with flexible plastics and want a real-world, actionable answer, you’re in the right place.

What Is TPE and Why Is It Hard to Shred?

TPE (Thermoplastic Elastomer) combines the elasticity of rubber with the processability of plastic. This hybrid nature makes it valuable—but also challenging.

Key properties of TPE:

- Highly elastic and flexible

- Softening under heat

- High tensile strength

- Tendency to wrap around shafts

According to industry data, over 65% of shredding issues with soft plastics come from material wrapping and heat buildup, not blade failure. That’s why standard plastic shredders often fail when processing TPE.

Can SUNY Group’s Shredder Shred TPE Successfully?

Yes—SUNY Group’s industrial shredders can shred TPE effectively, provided the shredder is correctly matched to the material form and production goals.

SUNY Group designs shredders specifically for:

- Soft plastics

- Elastomers

- Rubber-like materials

- Mixed plastic waste

Their machines are widely used in plastic recycling, e-waste recycling, automotive waste processing, and composite material separation, where flexible materials are common.

Which SUNY Group Shredder Works Best for TPE?

Not all shredders are created equal. For TPE, low-speed, high-torque shredders perform best.

Recommended SUNY Group configurations:

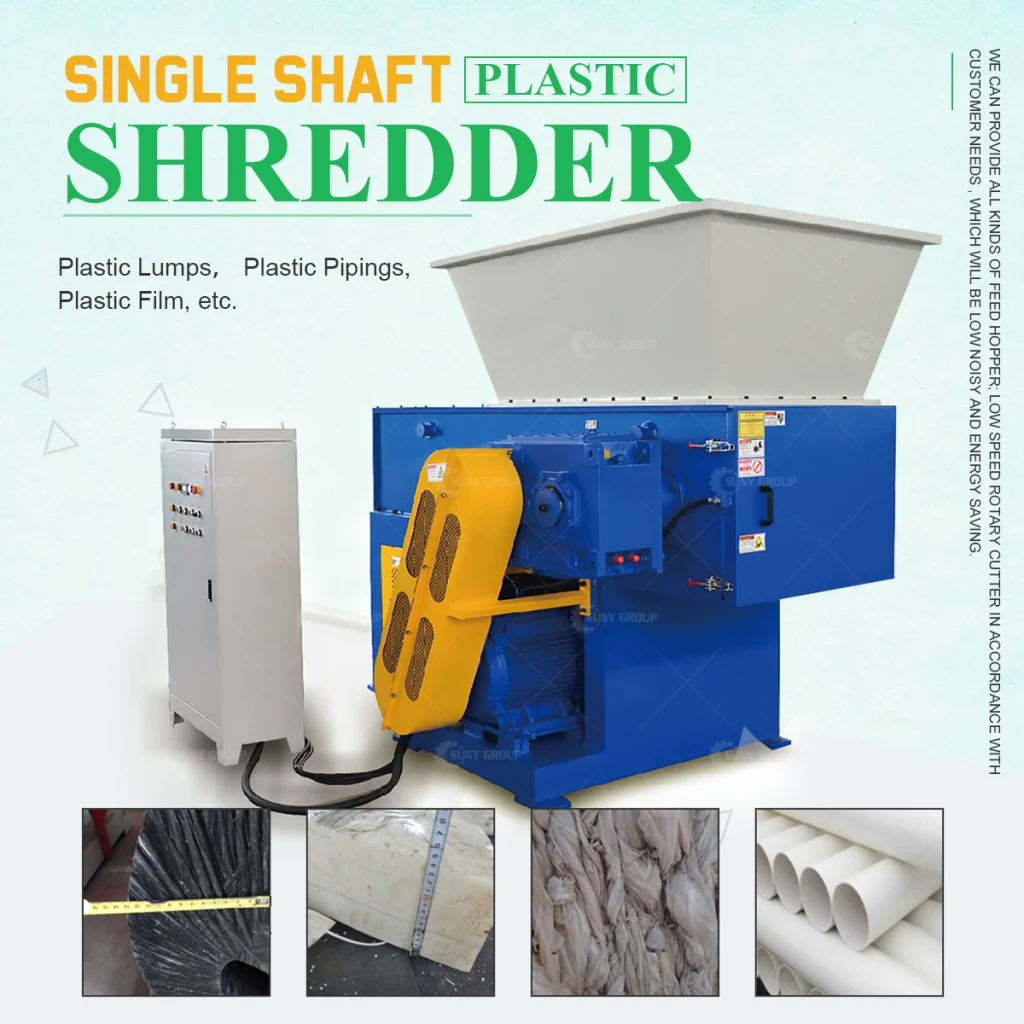

1. Single-Shaft Shredder (Heavy-Duty)

Best for:

- TPE sheets

- TPE scrap blocks

- Injection molding waste

Why it works:

Slow rotation prevents heat buildup

Hydraulic pusher ensures continuous feeding

Anti-wrapping rotor design

2. Dual-Shaft Shredder

Best for:

- Thick TPE lumps

- Mixed TPE with rigid plastics

- Pre-shredding before granulation

Why it works:

- High torque tears instead of cuts

- Self-cleaning shaft interaction

- Excellent for bulky or contaminated material

Frequently Asked Questions About Shredding TPE

1. Will TPE melt during shredding?

Not with SUNY Group’s low-speed shredders. Their machines operate at under 30 RPM, minimizing friction heat and preventing melting.

2. Does TPE wrap around the shaft?

Standard shredders struggle here—but SUNY Group uses:

- Special rotor geometry

- Optimized cutter spacing

- Anti-winding blade profiles

These features significantly reduce wrapping risks.

3. Can SUNY Group shred soft and hard TPE together?

Yes. Mixed-density TPE streams can be processed with:

- Reinforced cutters

- Adjustable screen sizes

- Controlled feed pressure

4. What output size can be achieved?

Typical output ranges from:

- 20–80 mm for pre-shredding

- 10–30 mm with secondary shredding

This makes the material suitable for granulation, extrusion, or separation systems.

5. Is TPE shredding energy-efficient?

Absolutely. SUNY Group shredders use up to 25% less energy than high-speed granulators when processing soft plastics, according to internal performance benchmarks.

So, can SUNY Group’s shredder shred TPE?

Yes—and when properly configured, it does so efficiently, cleanly, and reliably.

TPE’s flexibility no longer has to be a bottleneck. With SUNY Group’s low-speed, high-torque shredding technology, recyclers and manufacturers can transform difficult elastic waste into valuable, reusable material.

If TPE is part of your waste stream, the right shredder isn’t optional—it’s essential.

Contact Us

Address

Henan Communication Industrial Park, Economic Development Zone, Zhengzhou City, Henan Province, China