Can shredders be used for electric vehicle batteries?

Imagine millions of electric vehicles (EVs) hitting the road. Now, imagine what happens ten years from now when those batteries die. It’s a mountain of waste waiting to happen. As the world shifts to green energy, we face a massive new challenge: how do we recycle these giant, powerful, and potentially dangerous lithium-ion batteries?

You might be wondering, “Can we just throw them in a shredder like an old car?”

It sounds simple, but the answer is a mix of yes, no, and it’s complicated. Shredding EV batteries isn’t just about crunching metal; it’s about handling high-voltage energy, preventing explosions, and recovering “black gold” (valuable metals).

Short Answer: Yes, but they need to be discharged first.

To answer the crucial question: Yes, shredders can be used on electric vehicle batteries. However, you need to discharge them first.

Electric vehicle batteries are complex chemical compositions containing lithium, cobalt, nickel, and residual electrical charge. When crushed, they can undergo “thermal runaway”—a chain reaction that causes the battery to overheat and catch fire. Therefore, the shredders used are highly specialized industrial equipment designed to operate under extreme conditions.

How it Works: The Science of Safe Shredding

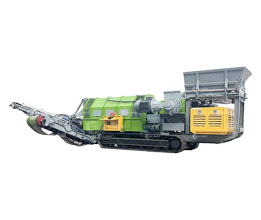

Discharging: Ideally, batteries are discharged before entering the shredder. Then, the crushing process is performed using metal shredders: These shredders utilize high-torque, low-speed shafts (typically dual or quad shafts) to grind rather than cut, thus reducing the risk of sparks.

Gas management: Special filtration systems capture toxic gases released during the shredding process, protecting workers and the environment.

Why is using shredders to process electric vehicle batteries a growing trend?

To understand the urgency, consider the following data. The global electric vehicle battery recycling market is expected to experience explosive growth.

Market growth: The market is projected to have a compound annual growth rate of over 21% between 2025 and 2030.

Recycling volume: By 2030, it is estimated that more than 2 million tons of lithium-ion batteries will reach the end of their lifespan annually.

Frequently Asked Questions (FAQ)

Q: Can fully charged electric vehicle batteries be shredded?

A: Standard safety procedures typically recommend discharging the battery first to minimize energy release.

Q: Is shredding better than dismantling?

A: It depends on the situation. Dismantling (manual or robotic disassembly of the battery) yields purer materials but is slower, more expensive, and dangerous for workers. Shredding is faster and cheaper.

Q: Is shredding harmful to the environment?

A: Yes, if gas capture is not performed during the shredding process. However, modern, specialized facilities use scrubbers to capture 99% of emissions. Furthermore, recycling avoids the significant environmental pollution caused by mining new metals.

Q: What happens to the plastic components?

A: During the sorting process (usually using air separation or magnetic separation), the steel casing and plastic separators are removed and sent to traditional recycling plants, leaving behind the valuable black mass.

Can shredders be used for electric vehicle batteries? Absolutely. In fact, they are the workhorses of the future green economy. As the first generation of EVs retires, these advanced shredding technologies will ensure that old batteries don’t become toxic waste but rather the seeds for the next generation of clean vehicles.

The transition to electric transport is not just about the cars we drive; it’s about the lifecycle of the power that moves them. With safe, efficient shredding, we are paving the way for a truly sustainable future.

Contact Us

Address

Henan Communication Industrial Park, Economic Development Zone, Zhengzhou City, Henan Province, China